sales@towerigllc.com

Commercial and Residential Insulated Glass

10-Year Warranty | Since 1991 | Certified Insulated Glass Manufacturer

10-Year Warranty

Since 1991

Certified Glass Manufacturer

Hours:

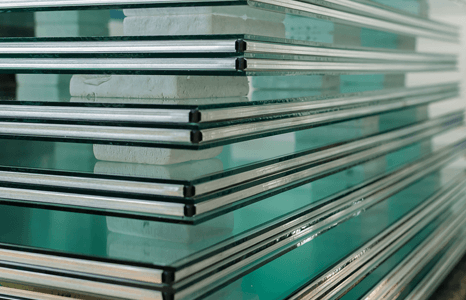

One of the Tri-State Area's Largest Glass Fabricators and Distributors

Based in North Bellmore, NY, Tower Insulating Glass LLC is one of the largest glass fabricators in the Tri-State area. Catering to commercial and residential customers, we’ve built a solid reputation as one of the best when it comes to quality and service. We use state-of-the-art equipment to manufacture glass products with precision. With specialized tools, we are able to create some of the largest glass units on the market today.

Don't limit your project's potential by working with another glass fabricator — choose Tower Insulating Glass LLC and put our more than three decades of experience to work for you. Call today to place your order.

Insulated Glass Experts

Since 1991, Tower Insulating Glass LLC has been consulting on projects and producing superior quality glass. Our team works with more than six brands of glass products and can help determine the best ones for your order. We are proud to be associated with both the Insulating Glass Certification Council (IGCC) and the Insulating Glass Manufacturers Alliance (IGMA). At Tower Insulating Glass LLC, we are dedicated to providing exceptional customer service and insulated glass units of the highest quality. This means that we are always looking for ways to improve through innovations in our industry and the advancement of the technology we use in production. When it comes to IG fabricators, you won't find anyone more skilled than the experts here at Tower Insulating Glass LLC!

When you work with Tower Insulating Glass LLC, we promise to give you nothing less than our very best. Call us today to discuss your next project with the industry's most reputable and reliable IG fabricators.

Customized Commercial & Residential Insulated Glass

No matter the size or scope of your project, the Tower Insulating Glass LLC team will have your order produced, inspected, and delivered with an unmatched level of excellence. Our facility and equipment allow us to create a wide range of glass units to suit any need. Whether you need large, textured panes or small, delicate stained glass, we have the tools and expertise to ensure your vision is brought to life.

Quality is essential to our craft. All of our units are inspected on at least four separate occasions to assure they meet the Tower Insulating Glass LLC standard. Furthermore, our facility is subject to audits performed by the American Society for Testing Materials. You can learn more about our qualifications, warranty, and specifications below.

Glass Products

Our assortment of products includes three types of monolithic glass – annealed, tempered, and laminated – and triple-glazed glass. Custom coatings and other features are available.

Warranty and Specifications

Our 10-year warranty is a valuable benefit we offer our customers. Our insulating units meet ratings established by the Insulating Glass Certification Council (IGCC).

Share On: